Customized Service

Design Your Own Custom Hardware

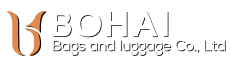

Behind every precision-engineered hardware product is a story of expertise, quality, and craftsmanship. Each custom component reflects decades of accumulated know-how and meticulous attention to detail.

The process of developing and producing custom hardware often requires extensive prototyping and skilled work by experienced engineers and technicians, ensuring every piece meets the highest standards of performance, durability, and reliability.

Custom Hardware Solutions

We understand that every project is unique, and so are your specifications. Our custom design services allow you to personalize your hardware to meet your exact requirements. Choose your preferred materials, finishes, and functional features to create hardware solutions that are truly tailored to your industrial needs.

Custom Industrial Solutions

Our hardware solutions are designed to empower businesses, providing reliable, high-quality components that enhance operational efficiency and project performance. We support skilled engineers and technicians, fostering a community of innovation, expertise, and professionalism. By choosing our products, you are partnering with a company that values craftsmanship, teamwork, and long-term success.

Precision-Engineered Hardware

Every hardware component is meticulously crafted with attention to detail. From precise measurements to polished finishes, we ensure that every element meets the highest standards. Our skilled engineers and technicians bring years of experience to each project, producing components that are both robust and reliable.

Customized Service Process

You should reach a professional design team for your product service

Requirement Communication

Understand customer requirements, provide preliminary solutions

Gather technical specifications and quality standards

Discuss project timeline and budget

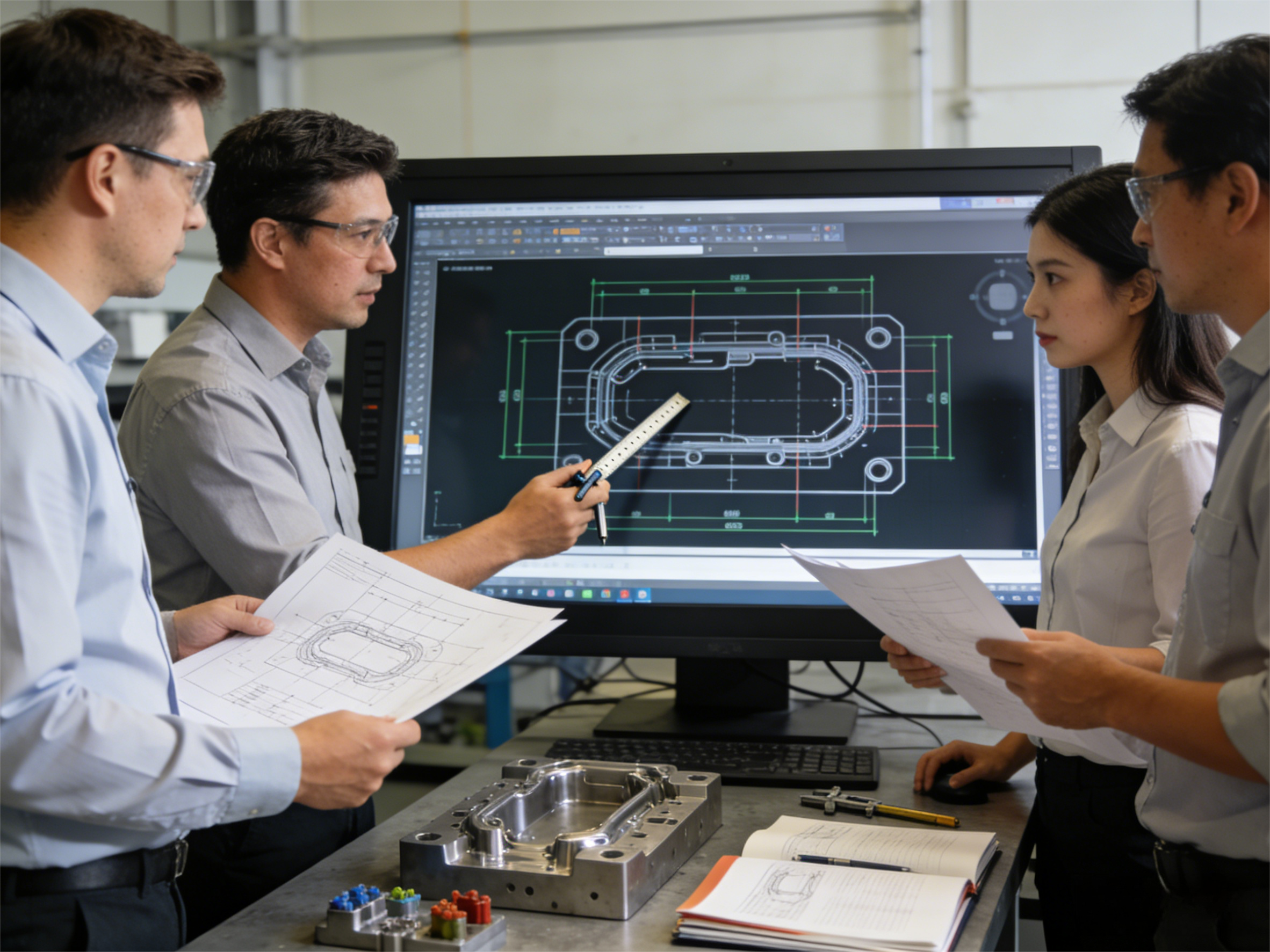

Design & Development

3D modeling and design optimization

Mold design and engineering analysis

Prototype production and testing

Mold Manufacturing

Precision mold processing

CNC machining of mold components

Mold assembly and testing

Mass Production

Production planning and scheduling

Raw material preparation

Quality-controlled manufacturing process

Quality Inspection

Comprehensive quality control at each stage

Dimensional accuracy testing

Surface finish evaluation

Functional testing

Packaging & Shipping

Customized packaging according to customer requirements

Labeling and documentation

Logistics arrangement and shipment

Delivery tracking

Service Advantages

20 Years of Mold Making Experience

Extensive expertise in mold design and manufacturing

Proven track record with various materials and complex geometries

Continuous improvement in mold efficiency and longevity

Professional Engineering Team Support

Skilled engineers with industry-specific knowledge

Dedicated project management for each customer

Technical support throughout the product lifecycle

One-Stop Service from Design to Delivery

Integrated service covering the entire production chain

Seamless coordination between departments

Single point of contact for all project needs

Time and cost efficiency through streamlined processes